Comprehensive Analysis for Optimizing Pellet Fuel Decisions

A FutureMetrics dashboard with that combines a calculation for storage and inventory requirements for a low capacity factor power station using white pellets with a calculator for determining the optimal choice between white or black pellets as fuel to replace coal.

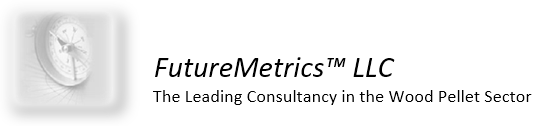

Calculate How Much Wood is Needed to Supply a Pellet Factory

This dashboard allows the user to estimate the annual demand for pellet production feedstock and biomass dryer fuel. It also estimates the annual wood costs.

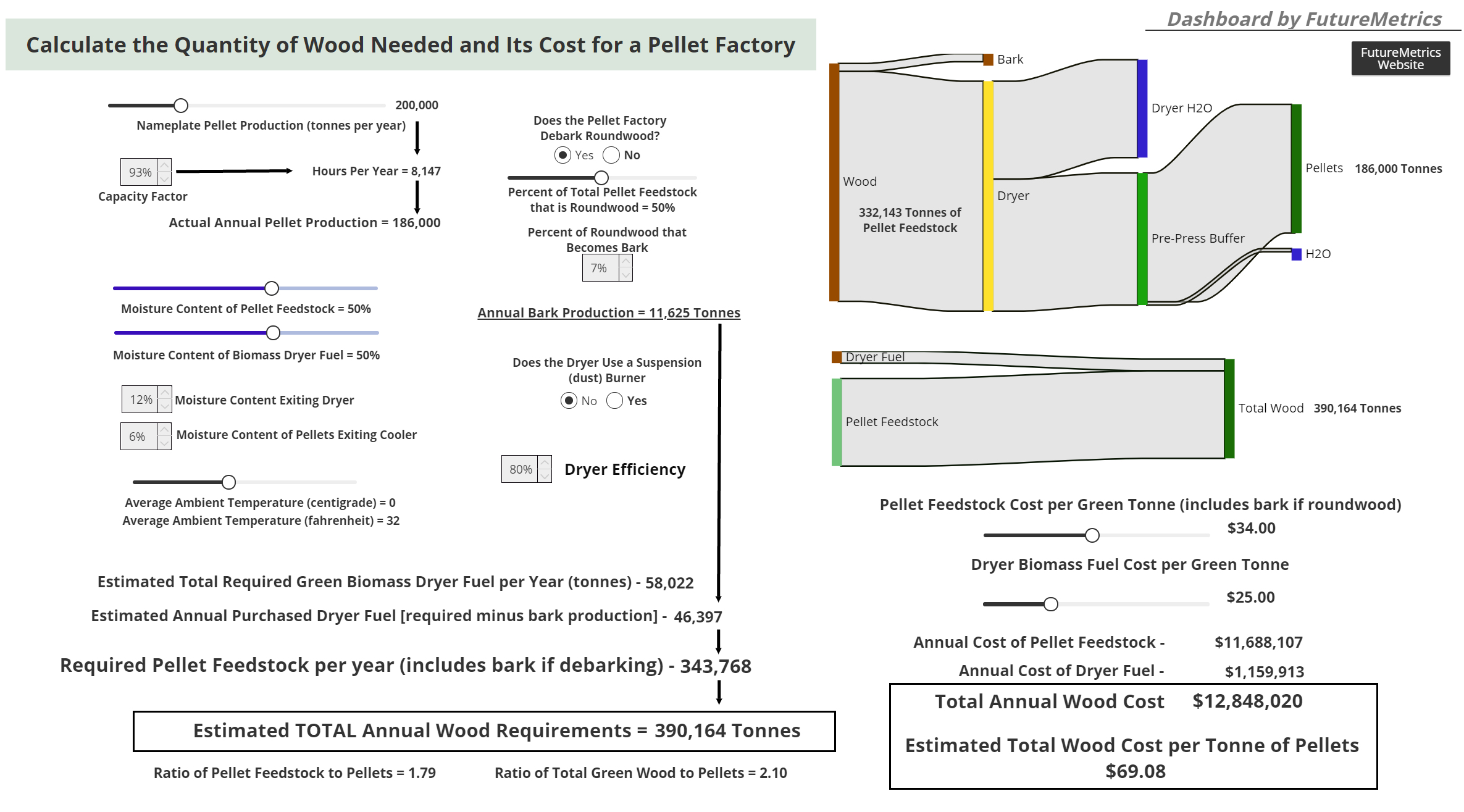

See How North America uses it Forest Resources

This dashboard show the actual breakdown of wood use capacities in the major sectors of the North American forest products industry*. The user can adjust a number of input assumptions that get from the nameplate capacity to actual use.

*Based on the Forisk North American Mill Capacity database, June 2023.

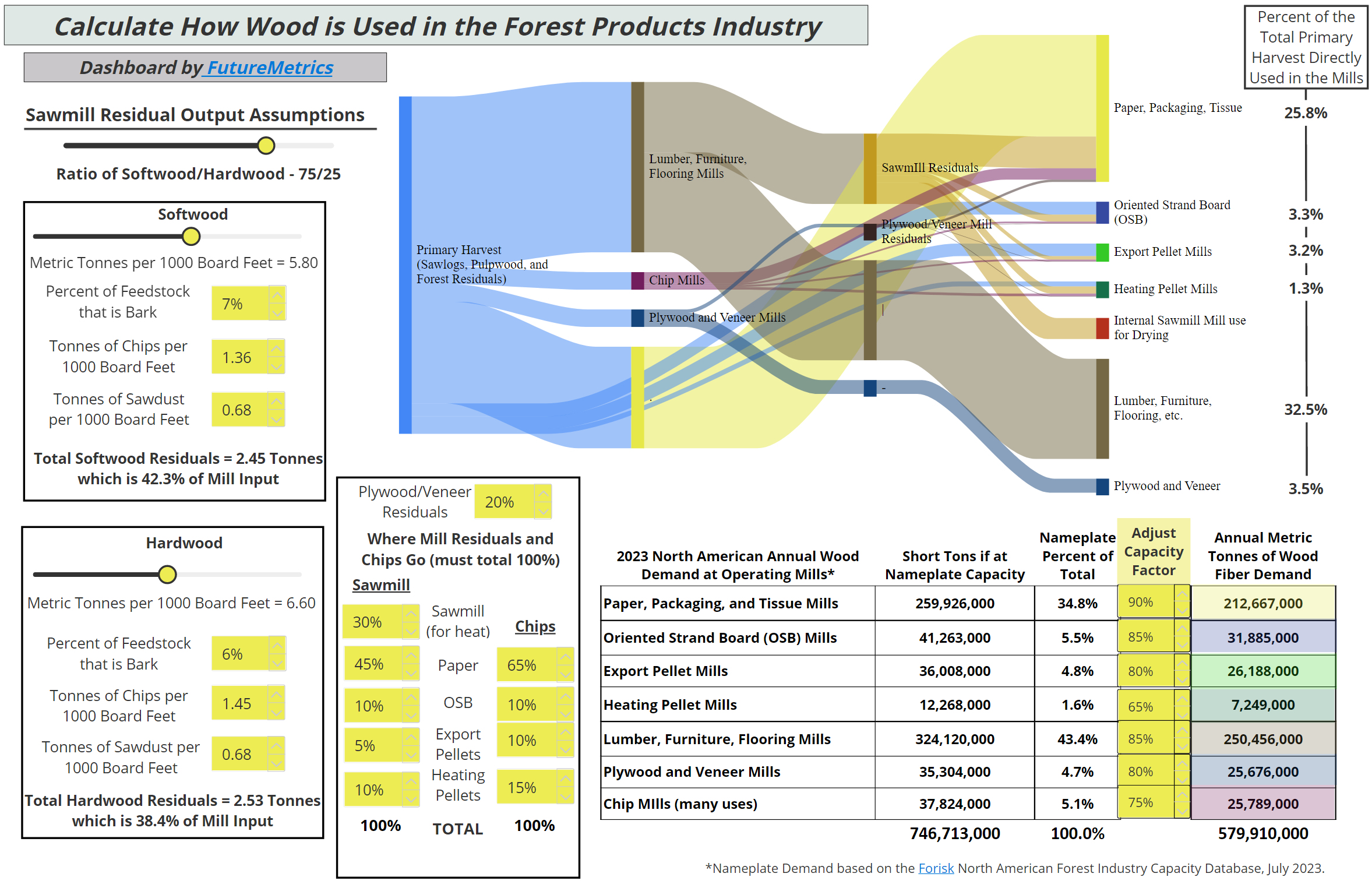

How much fuel is needed for a fluidized bed boiler power station using a blend of biomass fuels?

This dashboard is inspired by the many new build fluid bed boilers in Japan that are designed to use a blend of pellet fuel, palm kernel shell (pks), and domestic wood chips. Calculate the metric tonnes per year needed for each of the fuel types based on a number of critical inputs.

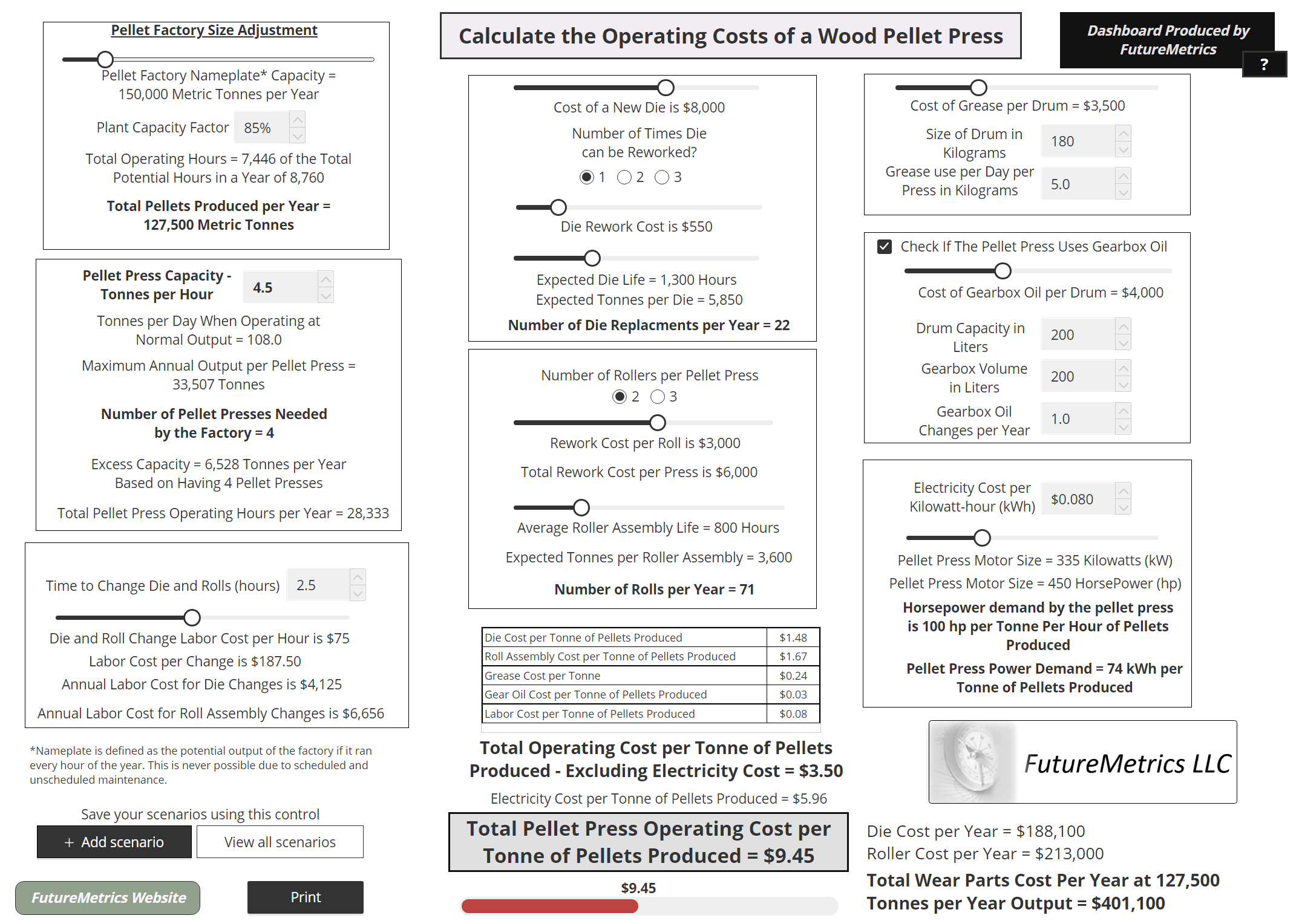

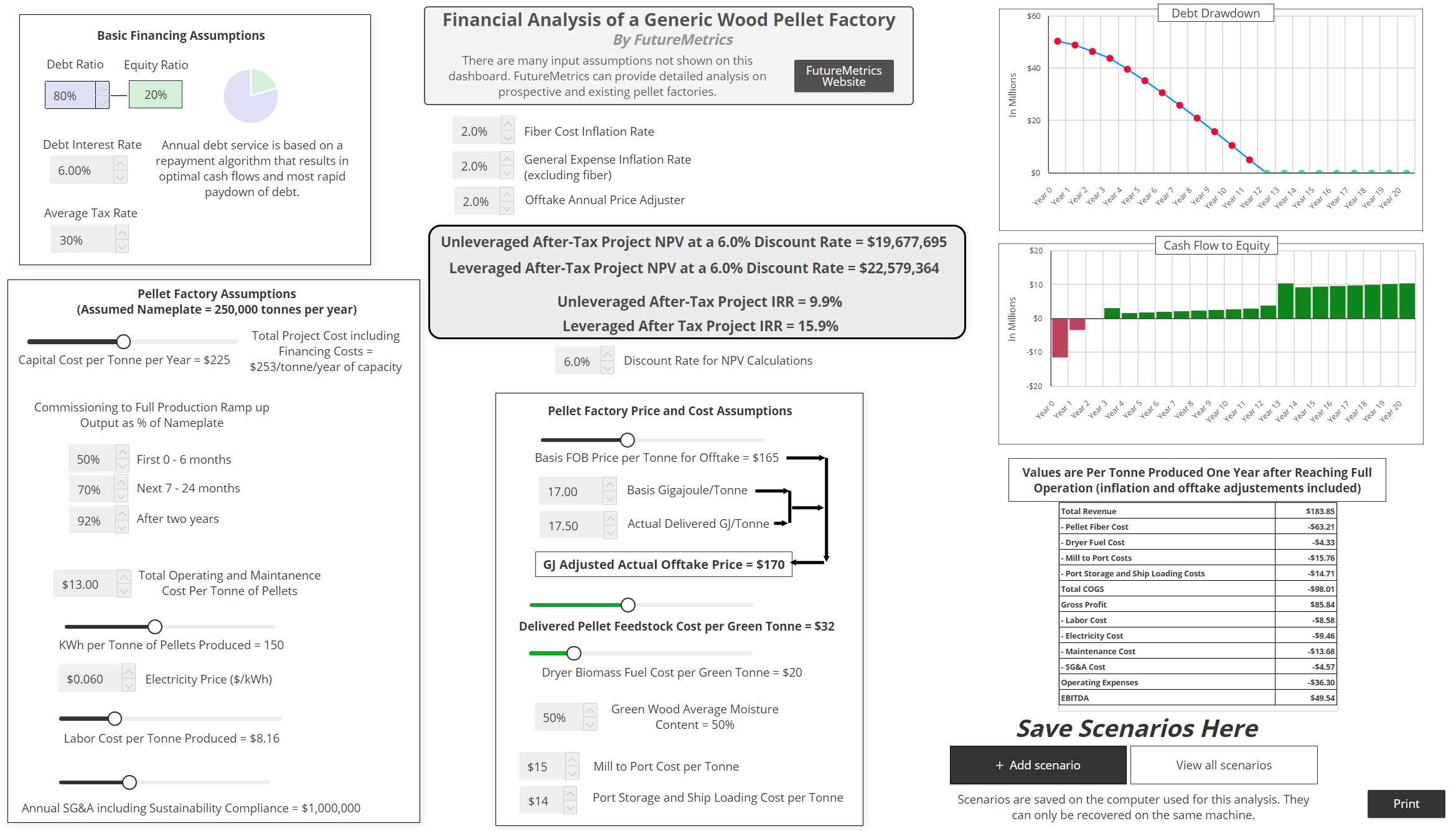

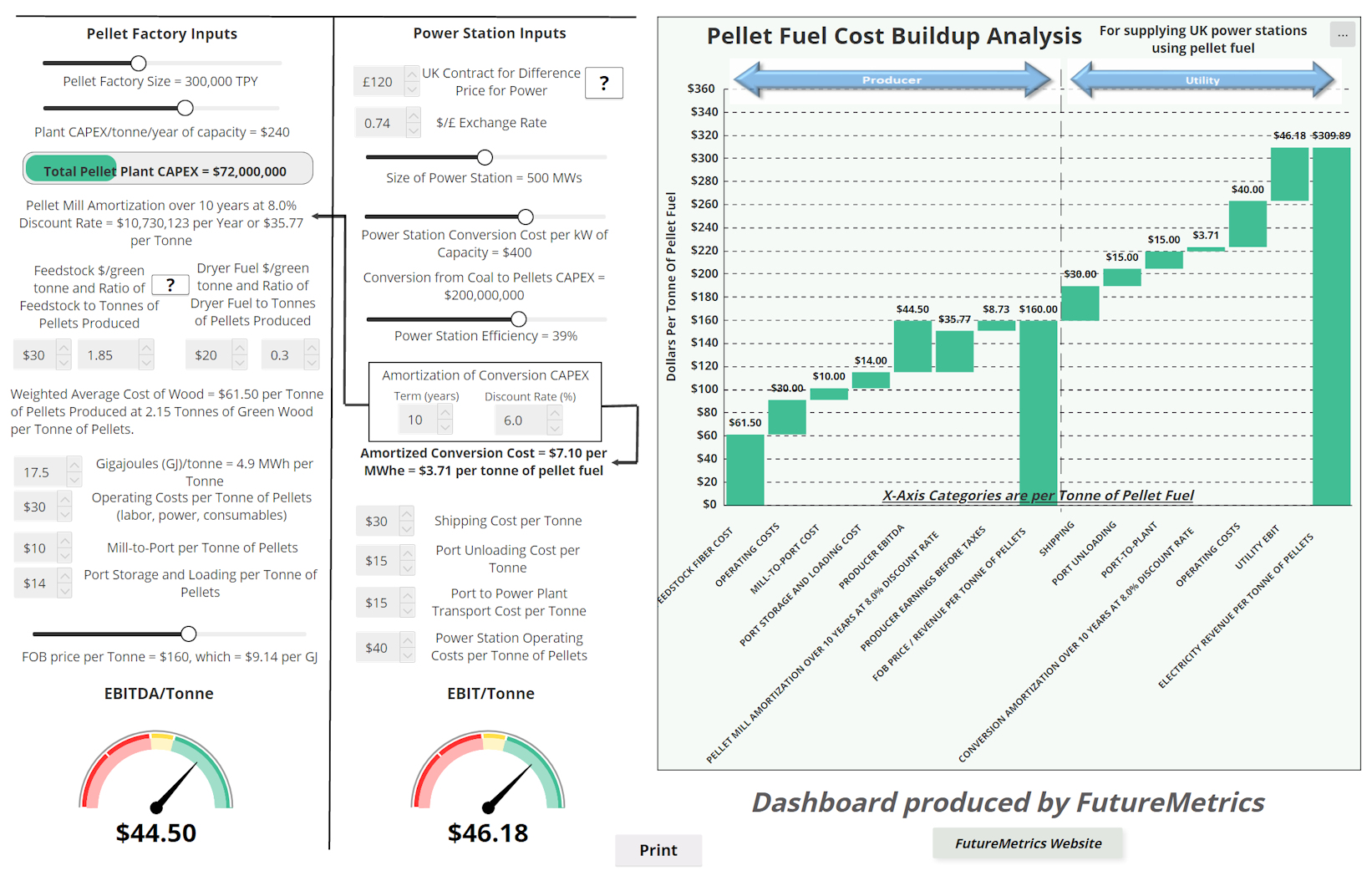

Calculate Return on Investment Metrics for a Pellet Factory

This dashboard allows the user to experiment with several of the critical cost and price inputs to a pellet factory financial model. See how sensitive the estimated cash flows are to mismatches between inflation rates and the annual offtake price adjuster.

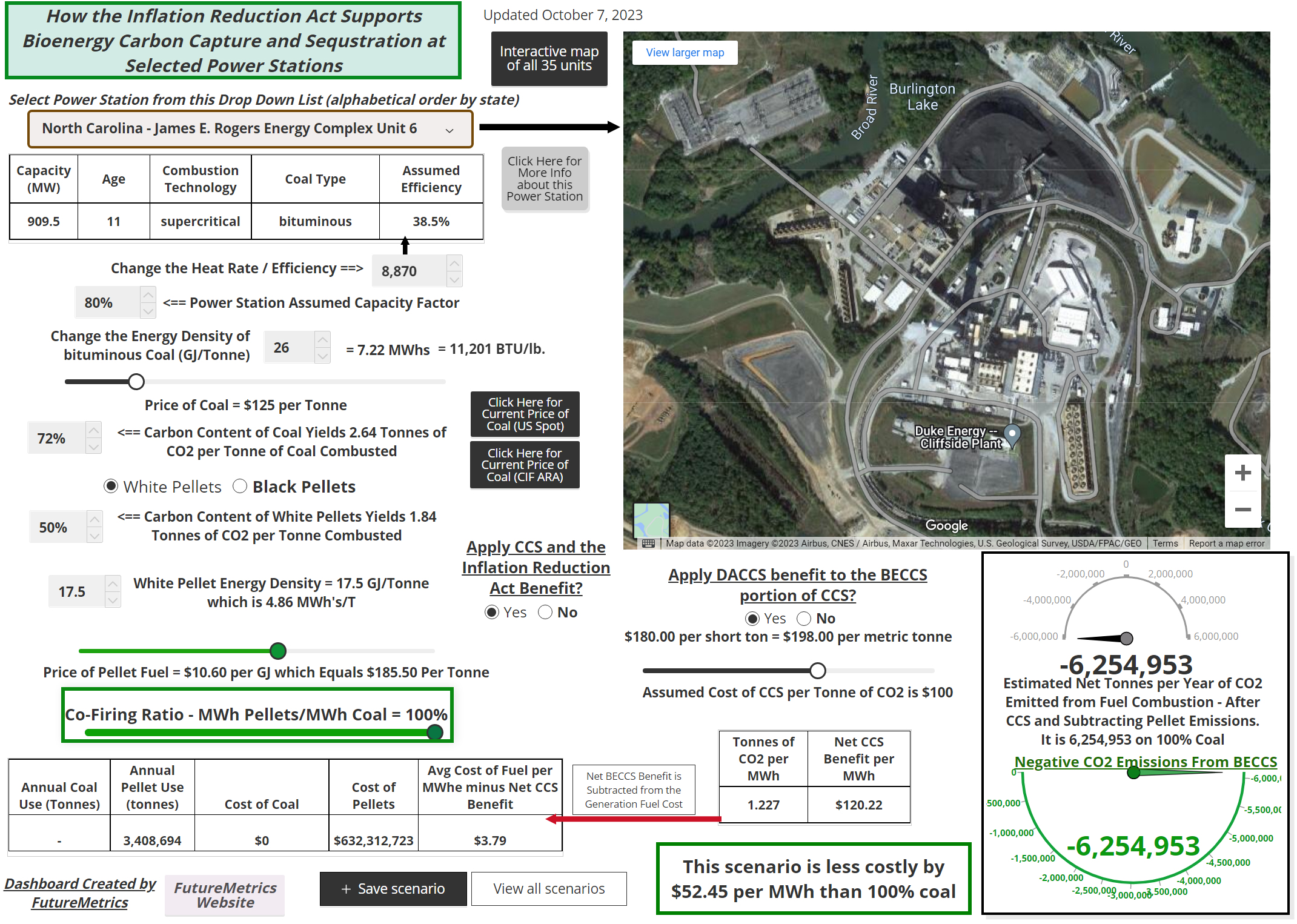

How the Inflation Reduction Act supports bioenergy carbon capture and sequestration at selected US power plants

The Inflation Reduction Act (IRA) has opened the door for what may be the most efficient and pragmatic approach to actively lowering atmospheric CO2 concentrations. This dashboard allows the user to experiment with many of the critical inputs that result in the net effect of the tax credits enabled by the IRA.

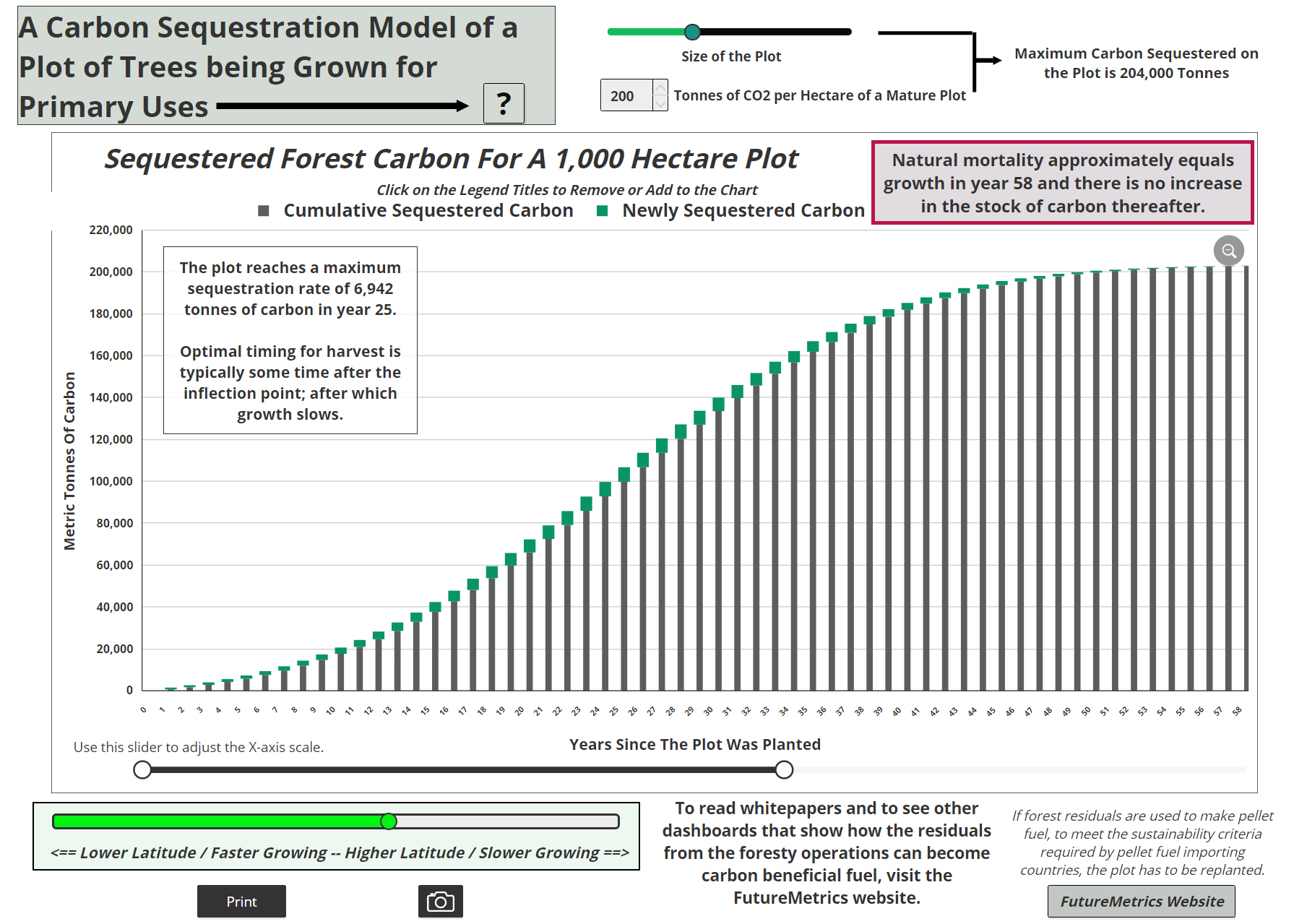

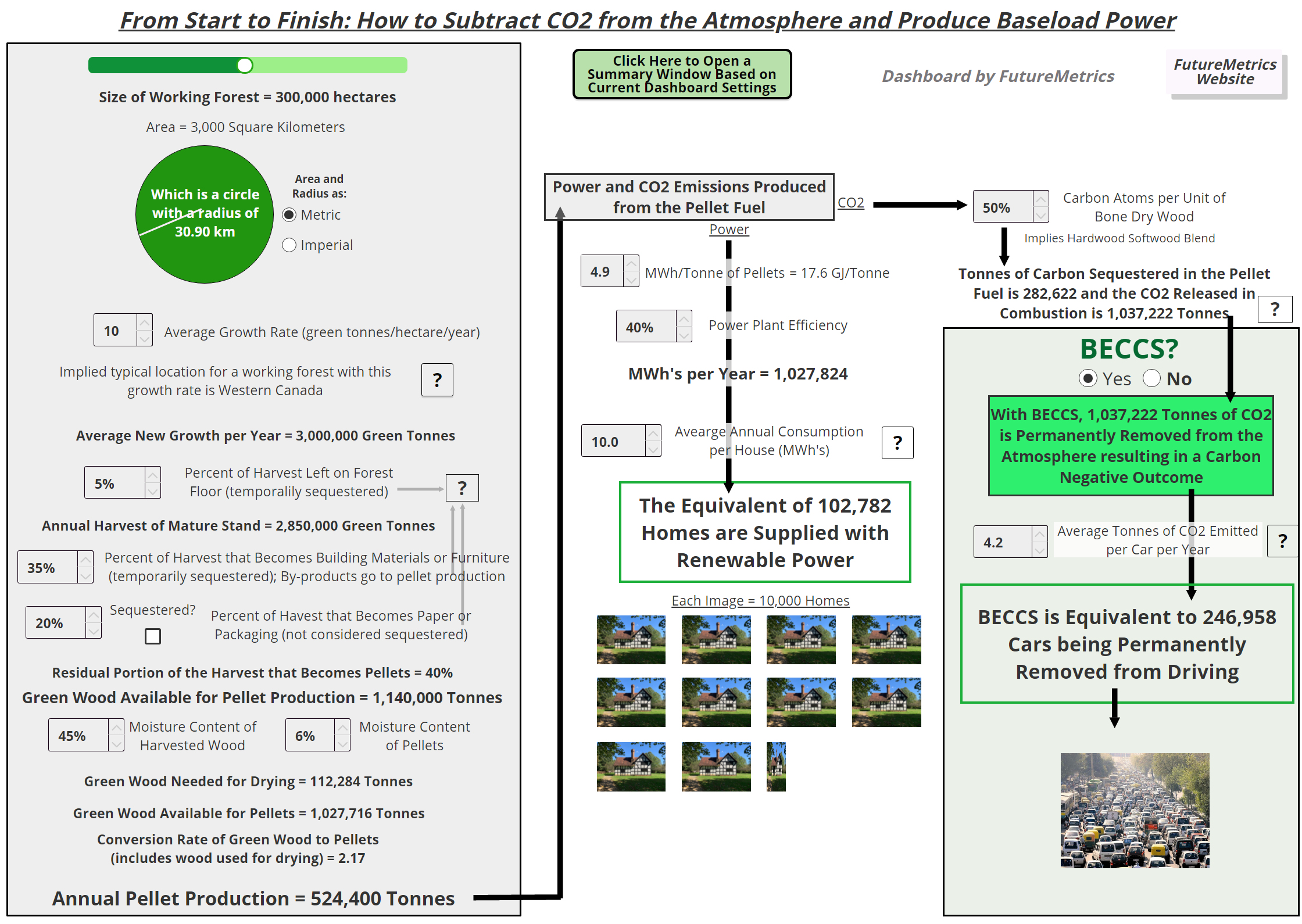

How Pulverized Coal (PC) Utility Power Stations can become an Integral Part of a Strategy for Removing CO2 from the Atmosphere

This dashboard tells a story that begins with a working forest landscape that is used to sustainably produce building products, pulp and paper, and wood pellets. The pellets are used in a PC power station that both makes power and, via carbon capture and sequestration (CCS), subtracts CO2 from the atmosphere.

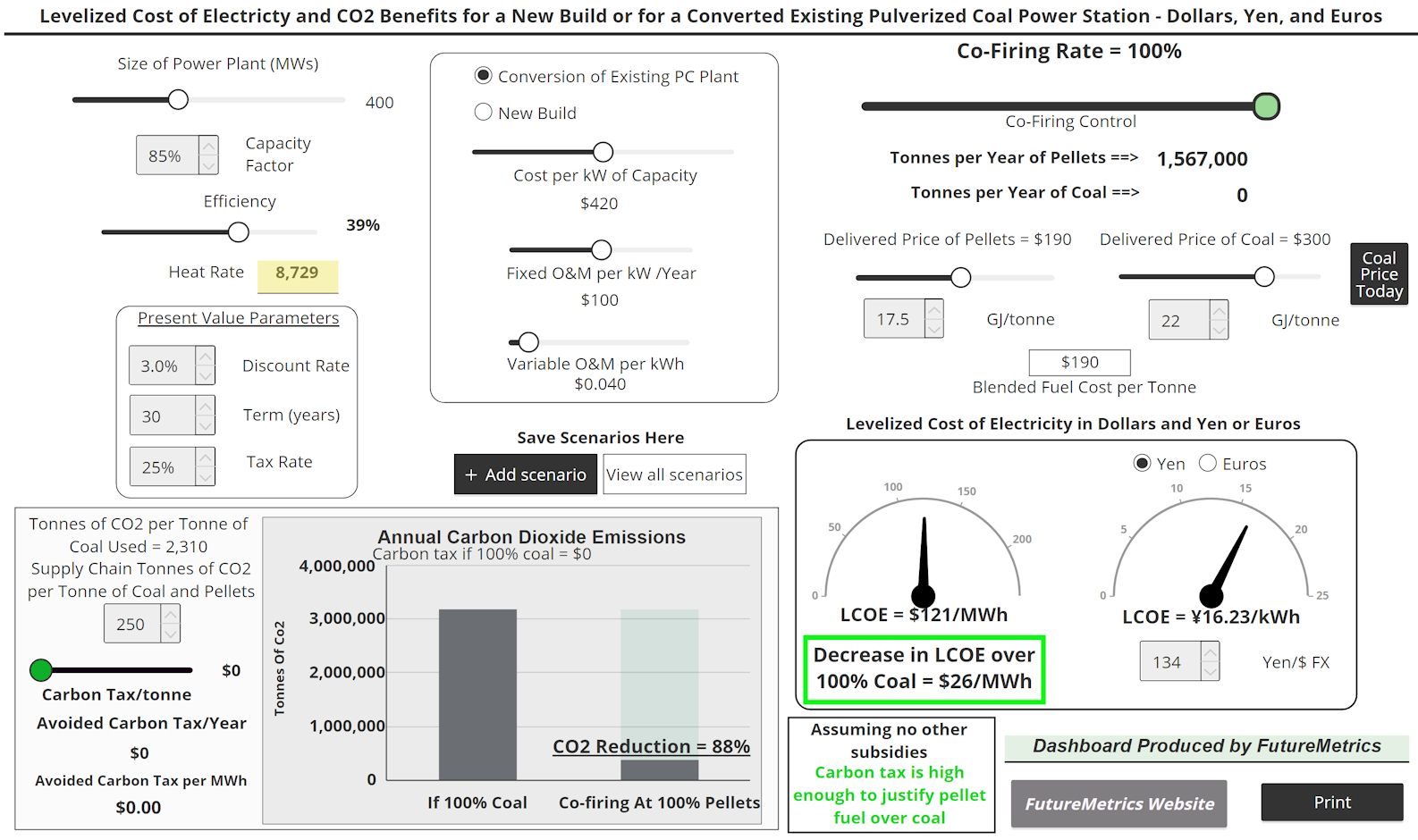

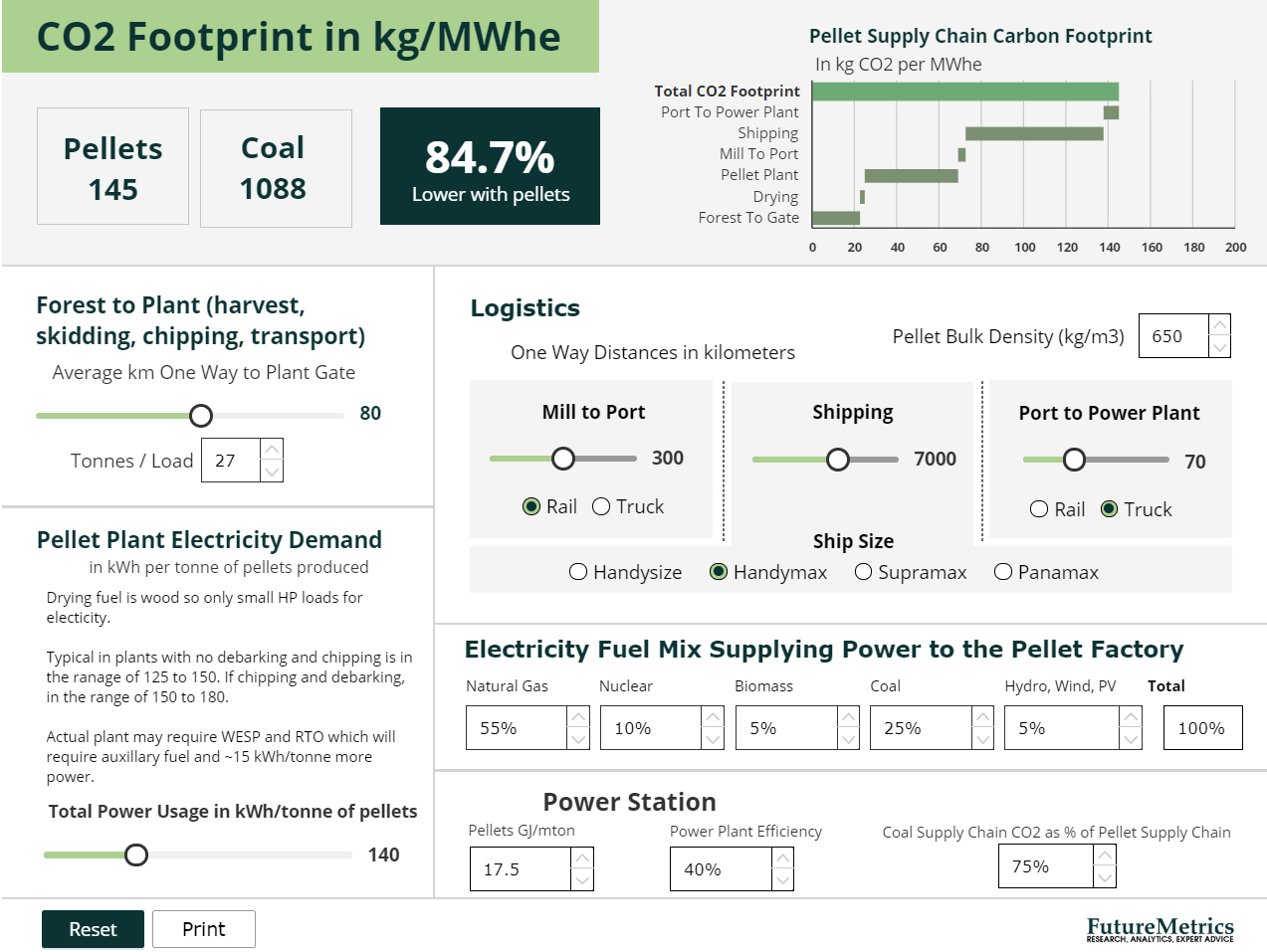

Calculate the Change in Costs for a Power Station that Substitutes Pellets for Coal

Calculate the Levelized Cost of Electricity (LCOE) for new build power stations and converted pulverized coal power stations. Pellet fuel from zero (100% coal) to 100% pellets. Carbon benefits are measured in avoided tonnes per year of emissions. LCOE can be viewed in Dollars, Yen, and Euros. Also shows the impact of a carbon tax.

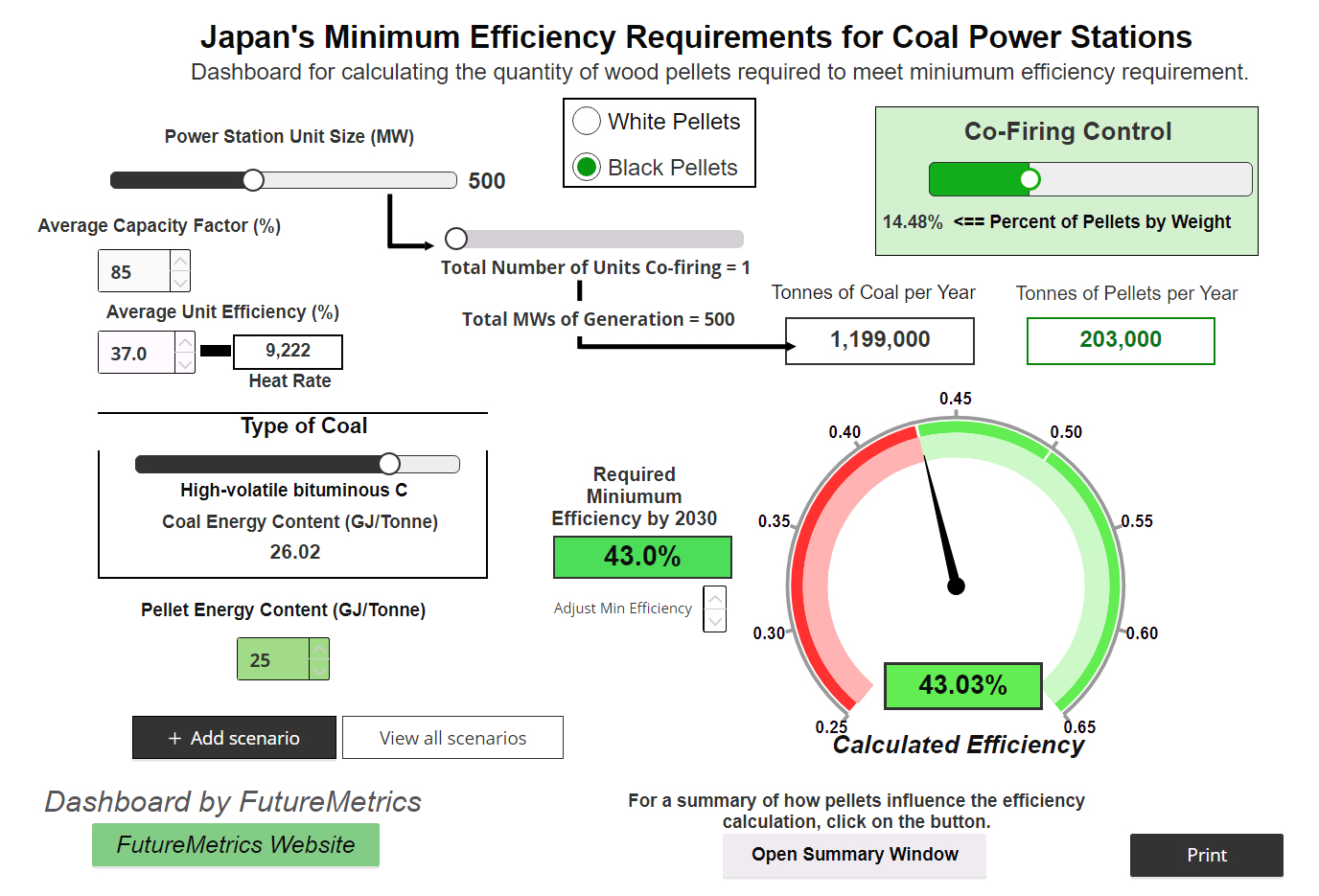

Japanese Minimum Efficiency Requirements for Power Plants

If a Japanese power plant’s efficiency is too low to comply with Japan’s minimum efficiency requirements for power stations, the power station can “increase” their efficiency by co-firing wood pellets. This dashboard calculate the annual tonnages of pellets that would be required to be in compliance.

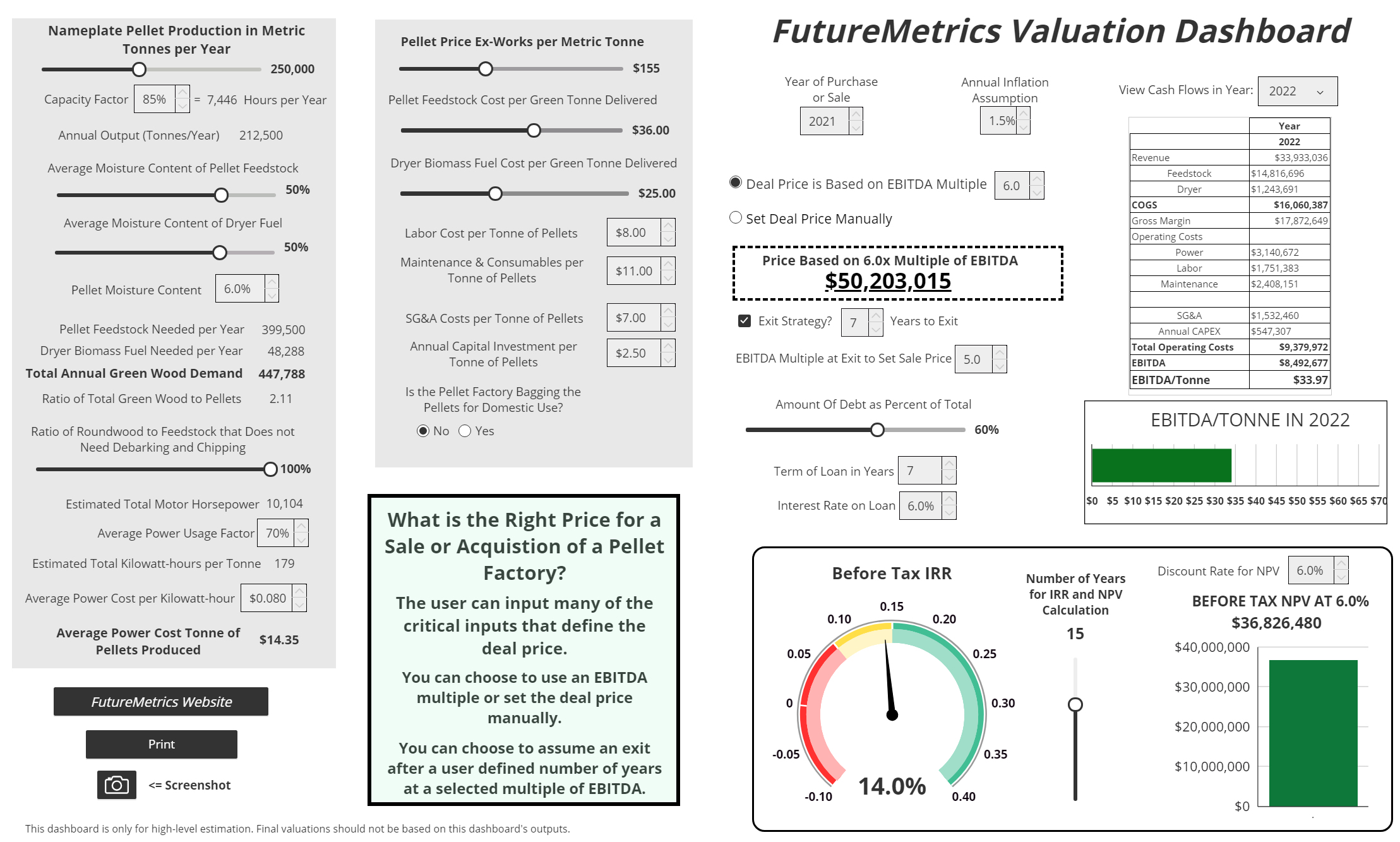

Valuation Dashboard

This comprehensive dashboard allows the user to work out the metrics for a sale or acquisition of an existing pellet factory. The user can adjust many of the critical inputs to the valuation model.

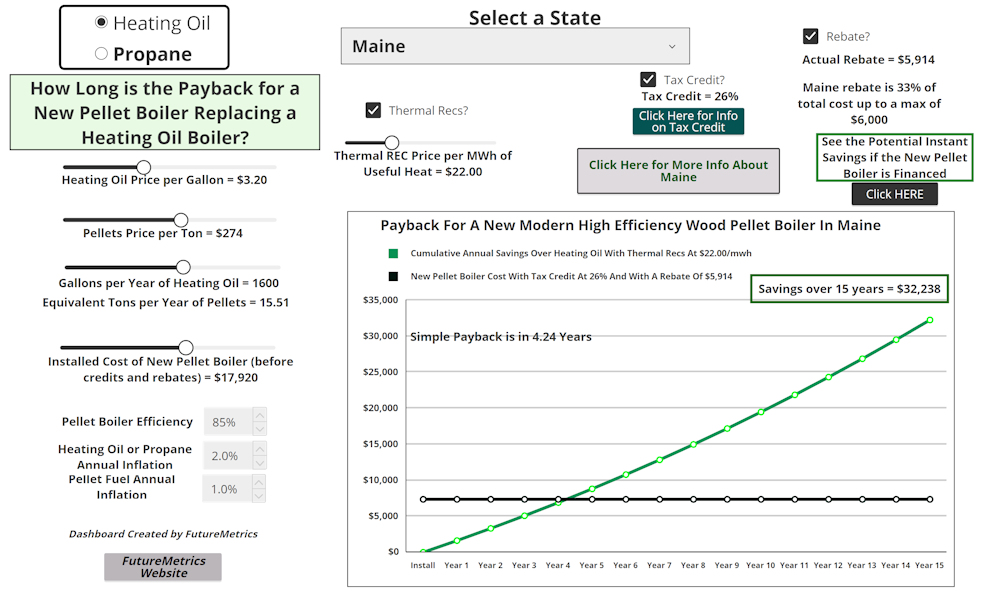

What is the Payback for a New Pellet Central Heating System Compared to Heating Oil or Propane?

This dashboard includes information on US tax credits, state rebates, and thermal renewable energy certificates (T-RECs). Adjust the installed cost, fuel prices, and other critical inputs to see how many years it takes for the payback of the investment in a modern fully automated pellet fueled central heating system.

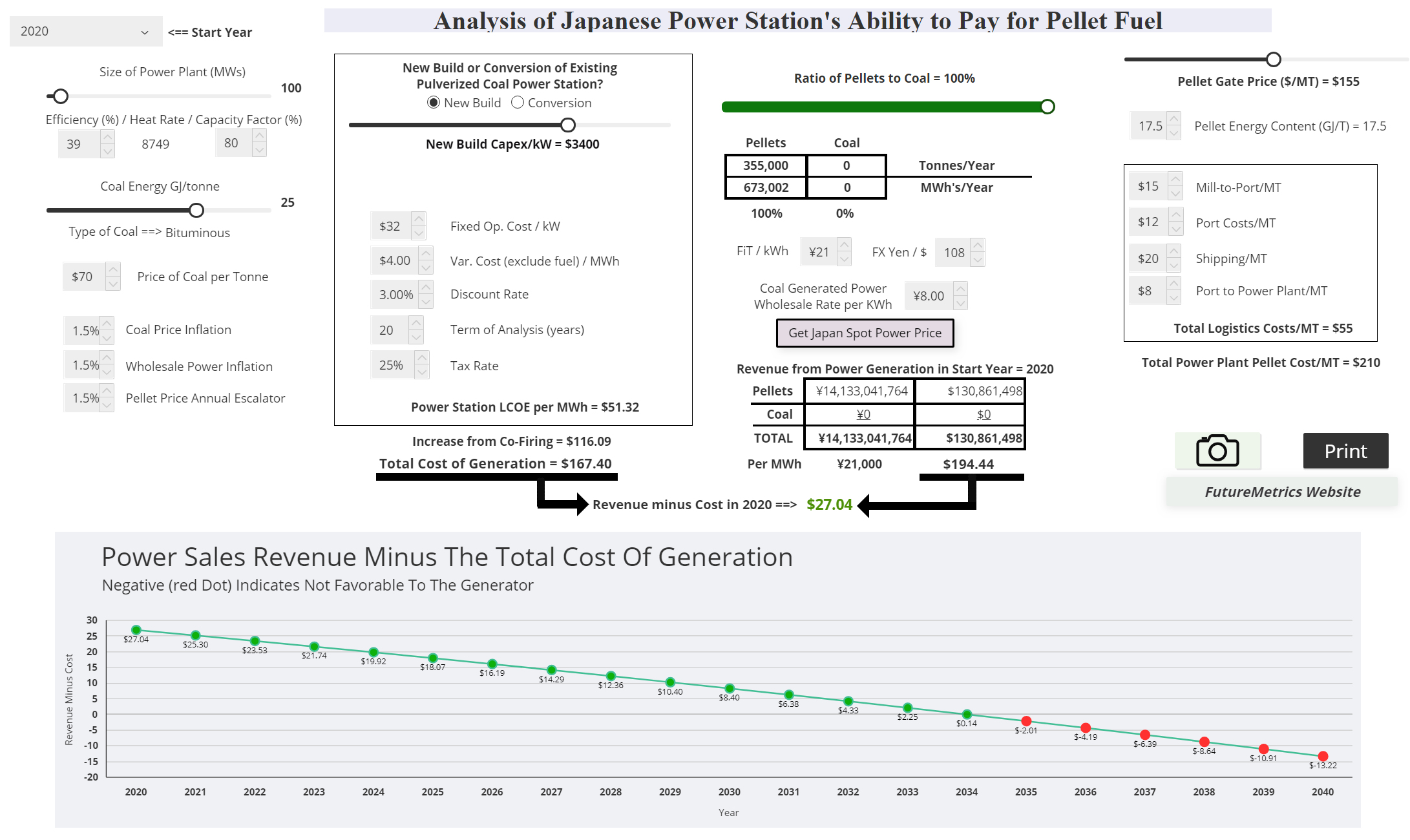

What is a Japanese Power Plant’s Ability to Pay for Pellet Fuel?

This dashboard has many inputs for calculating the total cost of generation versus the total revenues from power sales (including feed-in-tariff sales from pellet generated power). It also shows the expected power plant margins over the 20-year span of the feed-in-tariff.

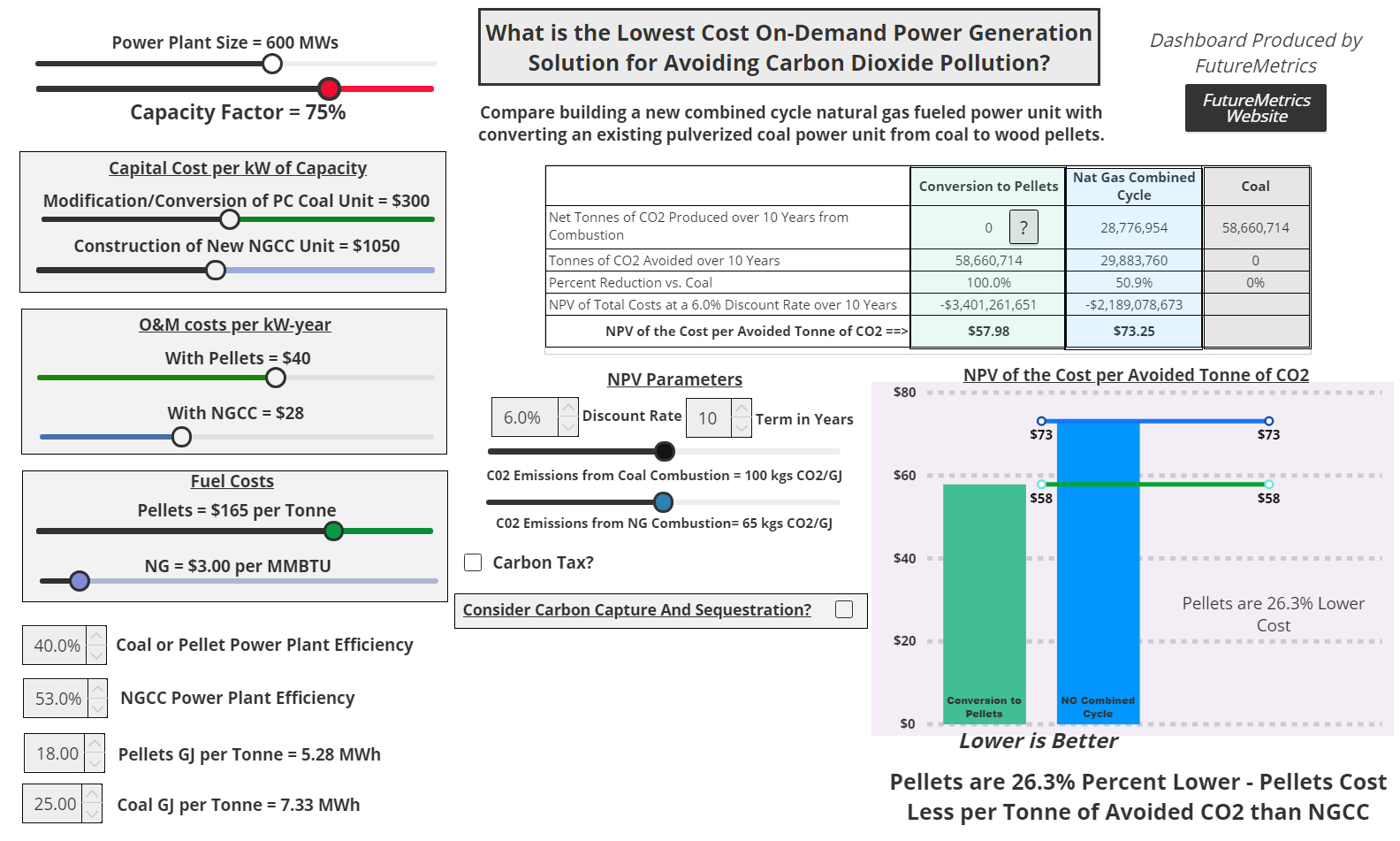

What is the lowest cost dispatchable solution for maximum decarbonization of the power sector?

This dashboard allows the user to compare the analytics of two scenarios that provide on-demand dispatchable power: (1) Retire coal power plants and replace them with new natural gas combined cycle generating stations, and (2) modify existing pulverized coal power plants to use renewable industrial wood pellets as a substitute for coal.

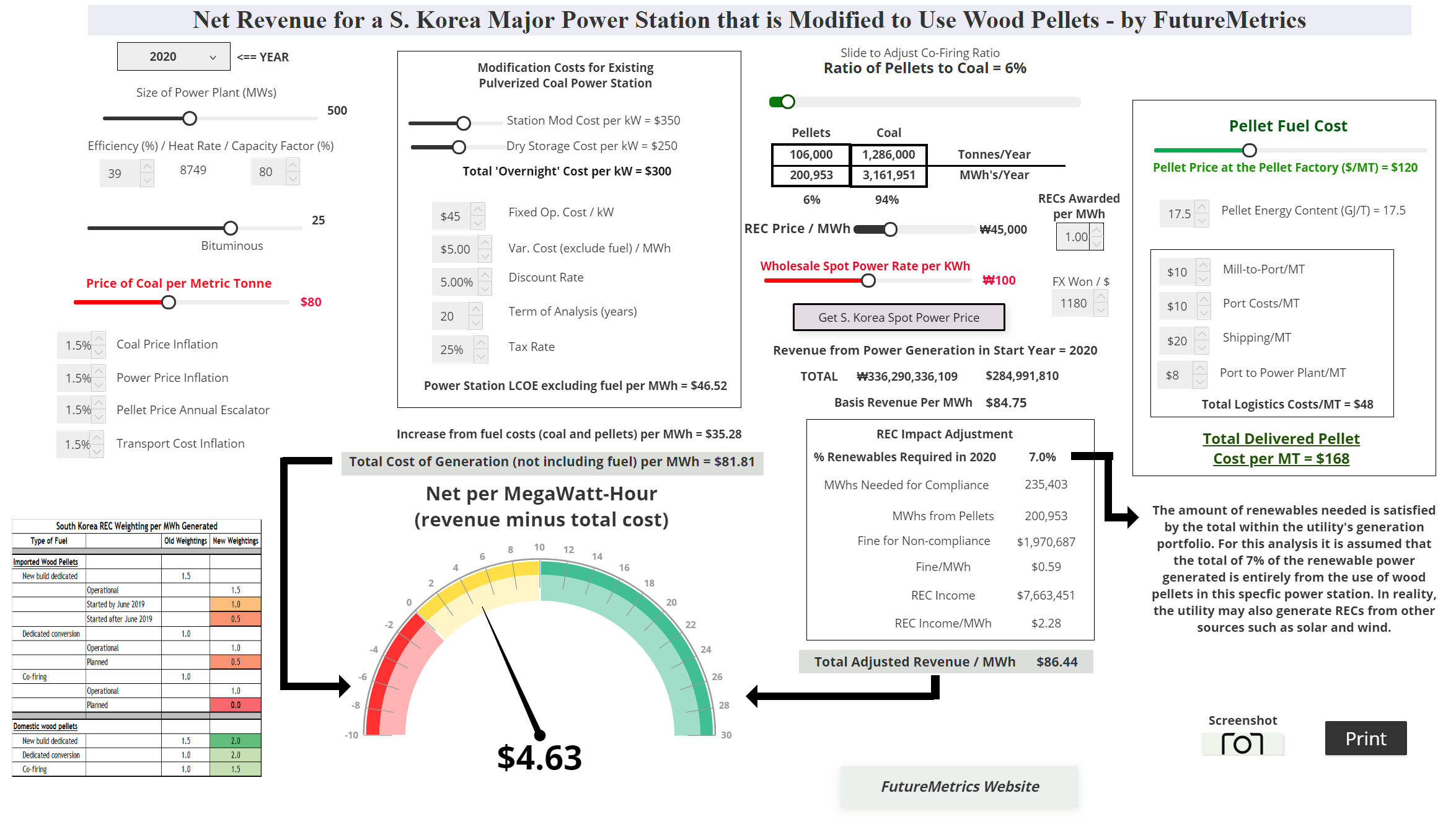

South Korean Power Station’s Ability to Pay for Pellet Fuel

See how a South Korean power plant can make (or lose) money under the S. Korean RPS scheme. Experiment with many inputs to see the net of revenue minus total costs when cofiring or full firing wood pellets and using RECs to supplement (or not) cash flows.